New Trends in Modular Construction: In-depth Analysis of the Construction Process and Technical Key Points of Fixed Container Houses

Against the backdrop of the global construction industry's continued pursuit of efficient, environmentally friendly, and low-cost construction methods, modular construction is gradually changing the traditional construction model with its significant advantages. As an innovative practitioner in this field, Shanghai Allstar Industrial Co., Ltd. has been deeply involved in the metal mobile integrated housing industry for nearly 20 years and has developed into a comprehensive enterprise integrating R&D design, intelligent manufacturing, engineering implementation, and after-sales service. Our modern production base in Hai'an, Nantong, Jiangsu, is equipped with internationally advanced production lines and an experienced professional technical team, capable of providing customers with full-process container building solutions from scheme design to construction implementation. The following will systematically explain the complete construction process and core technical key points of fixed container houses in combination with our company's rich project experience.

1. Preliminary planning and refined design stage

At the beginning of the project, the professional design team will conduct multiple rounds of in-depth communication with the customer to fully understand the project positioning, functional requirements, and budget range. Based on these key information, our designers will use BIM (Building Information Modeling) technology for three-dimensional visualization design, and accurately present the building's appearance, internal space layout, and pipeline direction through digital modeling. During this phase, we pay special attention to the following aspects:

Structural safety analysis: Calculate the load-bearing capacity of the container and optimize the structural design according to the climate conditions (such as typhoon and earthquake zones) and load requirements of the project location;

Code compliance review: Ensure that the design plan fully complies with international container building standards (such as ISO 668) and local building regulations;

Space utilization optimization: Through modular combination design, efficient use of space is achieved to meet the use needs in different scenarios.

2. Factory prefabrication intelligent manufacturing stage

After obtaining the design plan confirmed by the customer, the project will enter the prefabrication production stage of our modern factory. The quality control at this stage is directly related to the quality of the final building. We ensure the production quality through the following measures:

Strict selection of raw materials: We use weather-resistant steel from high-quality suppliers such as Baosteel to ensure that the main structure of the box has excellent corrosion resistance and structural strength;

Automated precision processing: We use advanced equipment such as CNC plasma cutting machines and automatic welding robots to ensure that the box size accuracy is within ±2mm;

Integrated pre-installation: More than 80% of the decoration work is completed in the factory, including insulation layer (optional polyurethane foam or rock wool), pre-buried water and electricity pipelines, door and window installation, etc.;

Strict quality inspection process: Quality inspection points are set up in each process, and the final product must pass air tightness, water tightness and load tests before it can be shipped.

3. Implementation of key technologies for on-site construction

(1) Professional foundation treatment

Based on the engineering geological survey report, our engineers will develop the optimal foundation plan. For permanent buildings, reinforced concrete strip foundations or raft foundations are usually used; for temporary buildings, adjustable steel support systems can be selected. Under special geological conditions (such as soft soil foundation), we will use pile foundation or foundation reinforcement measures to ensure stability.

(2) Modular lifting and precise docking

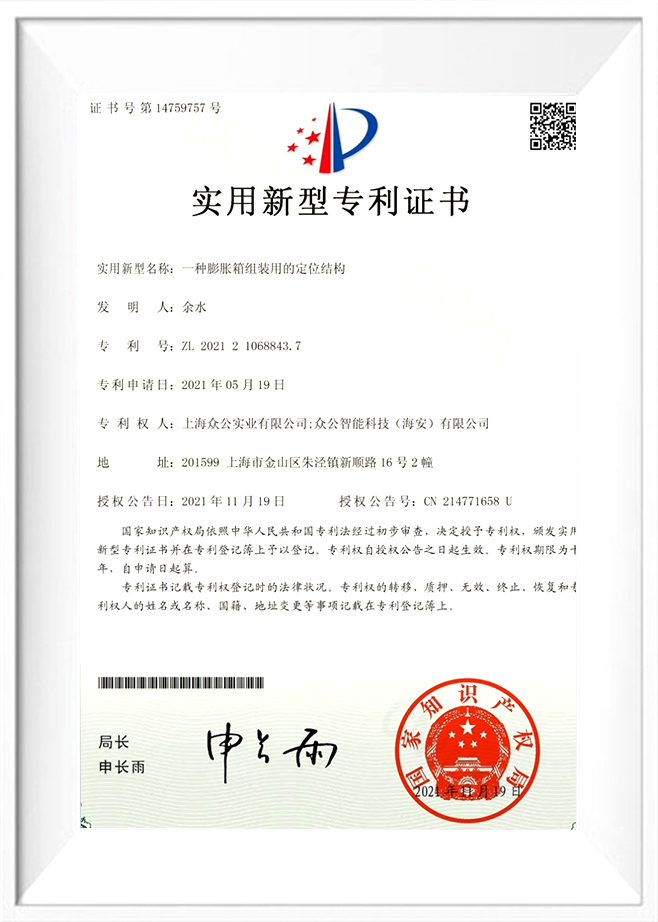

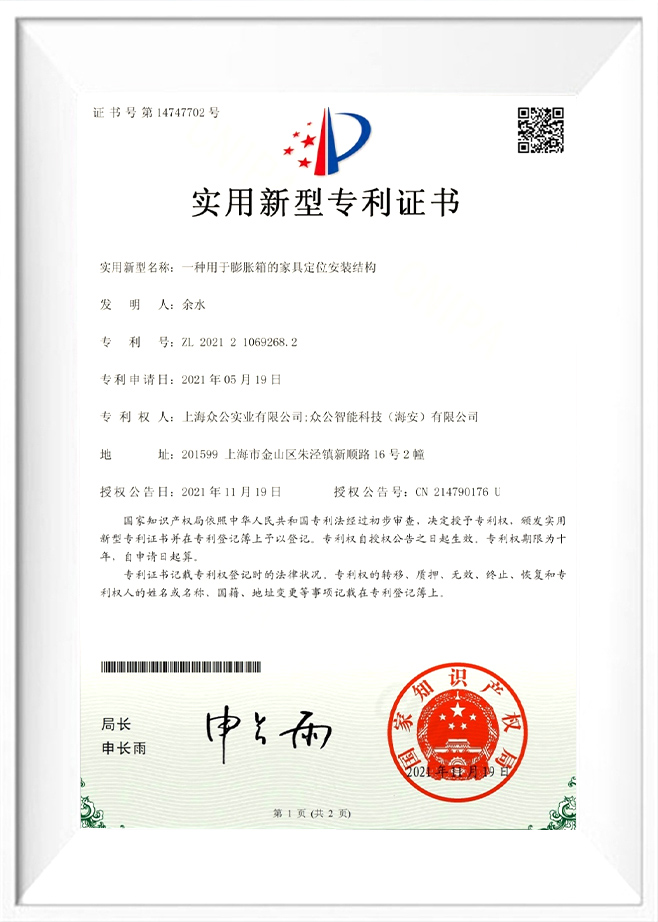

Use cranes above 200 tons for box lifting. Through our patented positioning and guiding device, the docking accuracy between adjacent boxes can be achieved within ±5mm. For multi-story buildings, we use a special steel structure frame reinforcement system to ensure the stability and seismic performance of the overall structure through a combination of high-strength bolt connection and welding.

(3) Mechanical and electrical system integration and debugging

The factory-installed water and electricity system is seamlessly connected to the on-site main pipeline. All electrical lines are protected by flame-retardant casings, and the water supply and drainage system is pressure tested. We pay special attention to:

Intelligent integration of energy systems, optional photovoltaic power generation systems and energy storage devices;

The use of fresh air heat exchange systems to improve indoor air quality;

The bathroom adopts an integrated waterproof chassis design to eliminate leakage risks.

4. Technological innovation and industry-leading advantages

Shanghai Allstar Industrial Co., Ltd. has always been committed to technological innovation. In recent years, we have focused on the research and development of a number of industry-leading technologies:

Green construction technology: The surface of the box adopts a nano self-cleaning coating to reduce maintenance costs; the roof can be integrated with a solar photovoltaic system to achieve carbon neutrality in the building;

Rapid construction system: Through highly standardized prefabrication production and parallel construction processes, the construction period can be shortened by more than 60% compared with traditional buildings;

Intelligent building system: Supports the integration of Internet of Things technology to achieve intelligent functions such as remote monitoring, intelligent security, and energy management;

Special environmental adaptability design: For extreme climates such as extreme cold and high heat, special solutions such as double-layer hollow glass and special insulation layers have been developed.

5. Shanghai Allstar's core competitiveness and industry commitment

As a benchmark enterprise in the modular building industry, Shanghai Allstar Industrial Co., Ltd. has always adhered to the business philosophy of "quality-based, innovation-driven, and service-oriented". We have:

Annual manufacturing capacity of 5,000 standard container modules;

A professional R&D and technical team of more than 50 people;

Project experience covering more than 20 countries and regions in Asia, Africa, Europe, etc.;

A complete after-sales service system, providing lifelong technical support.

From design consultation to construction delivery, we provide customers with a worry-free one-stop service. Whether it is emergency medical facilities, cultural and tourism resort projects, or permanent residential communities, we can provide the most competitive container building solutions. In the future, we will continue to deepen technological innovation and promote the modular construction industry to a greener and smarter direction.

English

English Español

Español عربى

عربى